Unleashing the Potential of Composite 3D Printing

Written by | Prableen Sachdeva

September 4, 2024

| 8:49 am

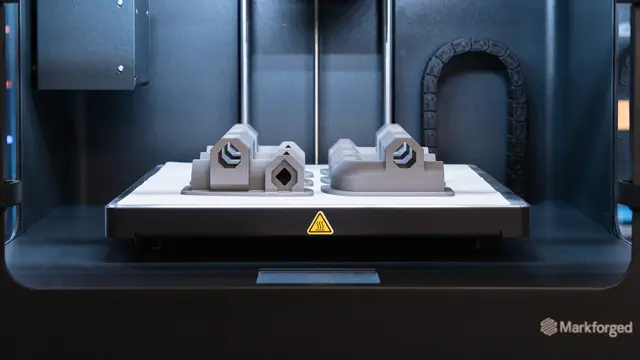

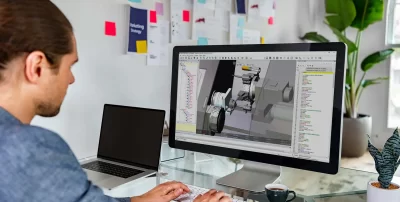

3D printing has emerged as a transformative technology, pushing the boundaries of what’s possible. Among the various advancements in this field, composite 3D printing stands out a game-changer, offering unparalleled strength, flexibility, and precision. Markforged, a leader in this innovative space, is at the forefront of providing cutting-edge solutions that redefine manufacturing processes across industries.