With Canada’s vast geography, reliance on imported goods, and strong focus on innovation, adopting AM is no longer just and option – it’s a strategic advantage. Here’s how additive manufacturing can help Canadian businesses future-proof their supply chains.

1. Shorter Lead Times & Localized Production

Many Canadian manufacturers rely on overseas suppliers for critical parts, making them vulnerable to long shipping times, trade restrictions, and unexpected delays. With AM, companies can produce parts on demand, right here in Canada.

This means:

- Faster turnaround times

- Fewer delays due to global disruptions

- Greater independence from foreign supply chains

Industries like aerospace, automotive, and healthcare are already leveraging AM to reduce their reliance on international suppliers and manufacture key components domestically.

2. Lower Cost in Logistics & Inventory Management

Traditional supply chains often require businesses to stockpile large inventories to avoid shortages. This ties up capital and increases storage costs.

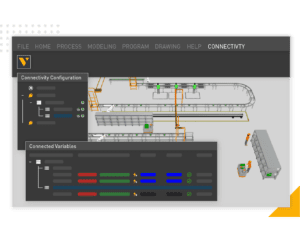

With AM, Canadian businesses can implement digital inventory strategies, producing parts only when needed. This significantly reduces warehouse storage costs, eliminates excess waste, and minimizes expensive last-minute shipping fees.

For businesses in remote regions – such as Northern Canada – where logistics can be especially costly and complex, on-site 3D printing offers a practical and cost-effective solution.

3. Design Flexibility & Faster Innovation

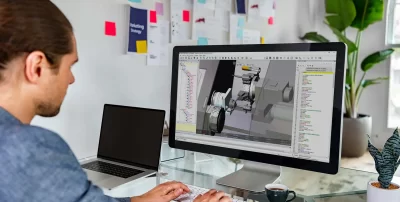

Canada is home to many world-class engineering and product development companies. AM allows designers and engineers to iterate quickly, test new ideas, and refine designs without costly molds or tooling.

Industries like medical device manufacturing, consumer goods, and industrial equipment benefit from AM’s ability to produce:

- Rapid prototypes for faster innovation

- Customized and complex parts with ease

- High-performance components optimized for strength and weight

4. Sustainable & Environmentally Friendly Manufacturing

With Canada’s commitment to net-zero emissions and sustainable production, businesses are under increasing pressure to adopt eco-friendly practices. Additive manufacturing helps by:

- Reducing material waste (printing only what’s needed)

- Cutting carbon emissions (by eliminating global shipping)

- Using recyclable and bio-based printing materials

Companies striving for a greener, more sustainable future can integrate AM to meet ESG goals while maintaining profitability.

5. Business Continuity & Risk Mitigation

Unexpected disruptions – whether a pandemic, labor strike, or geopolitical conflict – can grind production to a halt. With AM, companies can continue operations even when traditional supply chains fail.

By shifting to digital manufacturing and decentralized production, Canadian businesses can:

- Reduce reliance on at-risk global suppliers

- Adapt quickly to supply chain shocks

- Ensure business continuity with local manufacturing