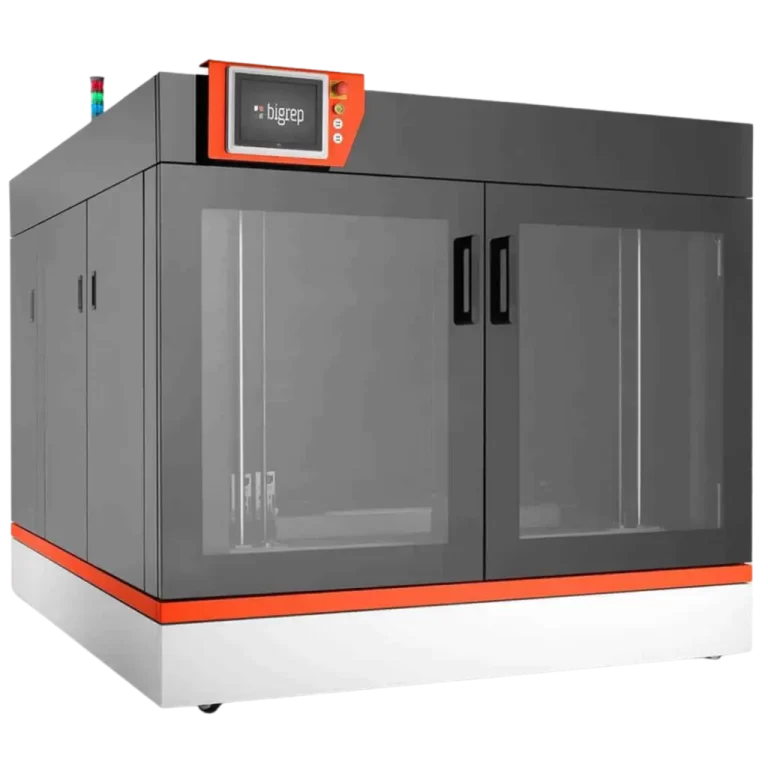

3D Printers

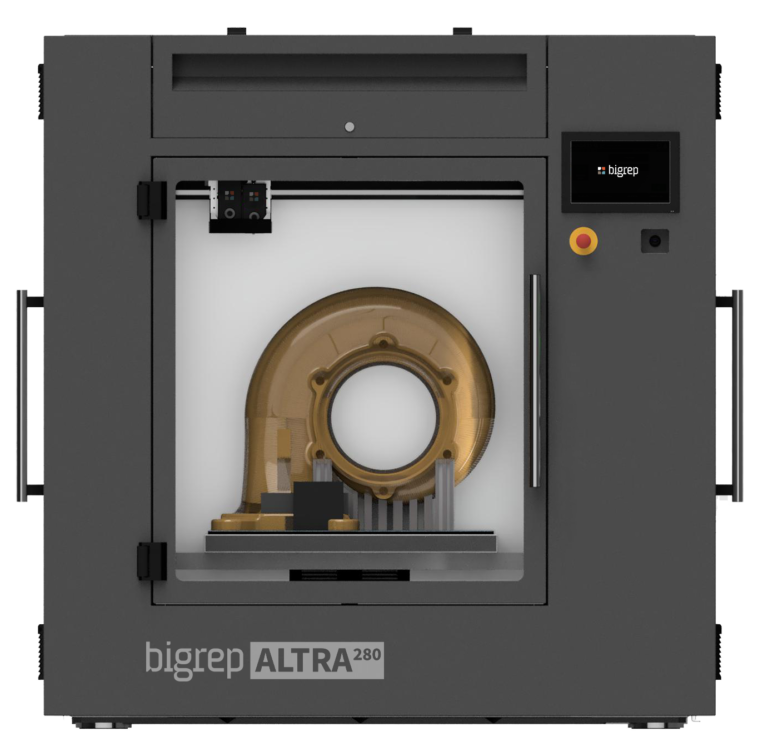

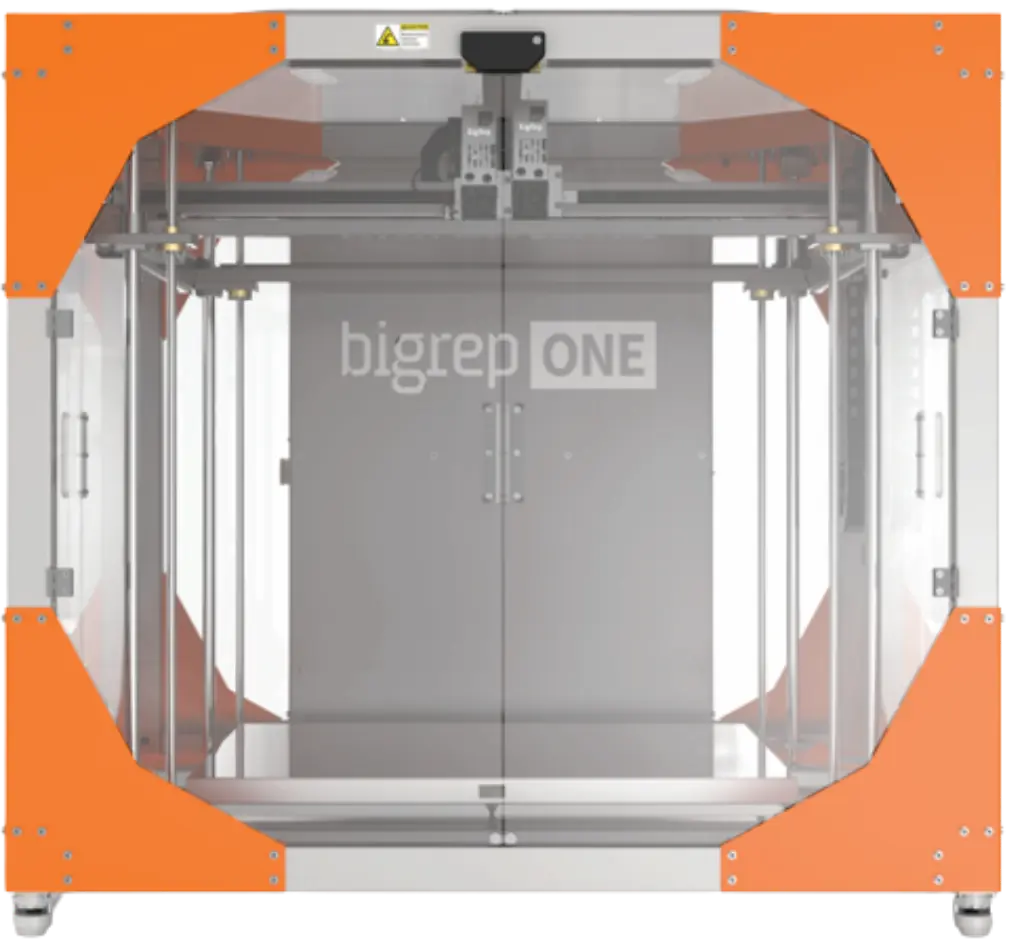

BigRep 3D printers

BigRep 3D printers are affordable and easy-to-use technology designed for large objects and ideas. Created for a range of industrial applications from rapid prototyping to finished products. Advance your manufacturing capabilities with BigRep printer’s size, speed, and agility – so you can get your products to market ahead of the competition.