How Additive Manufacturing is being leveraged for Investment Casting

April 20, 2021

| 9:06 am

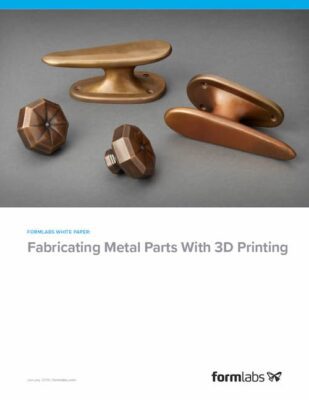

The investment casting AM process uses the injection of metal into a mold. The prototype is typically 3D printed using wax and it is a perfect replica of the final product. A mold made in plaster is poured over the prototype and the liquid metal is injected inside the mold to replace the wax prototype, which is finally melted away.

is one of the oldest metal-forming practices. Its ease of use and ability to produce

is one of the oldest metal-forming practices. Its ease of use and ability to produce