Embracing Industry 4.0 in the Military & Defense Sector: A Technological Transformation

Written by | Prableen Sachdeva

January 15, 2025

| 8:52 am

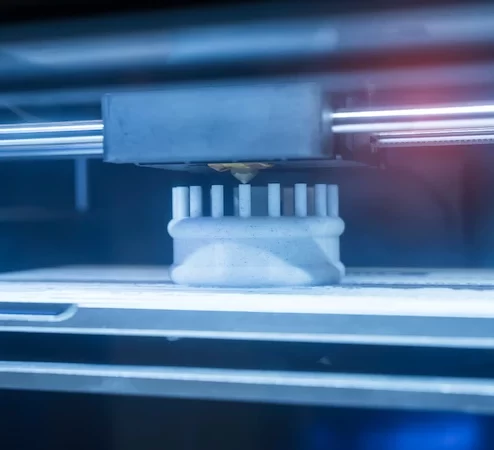

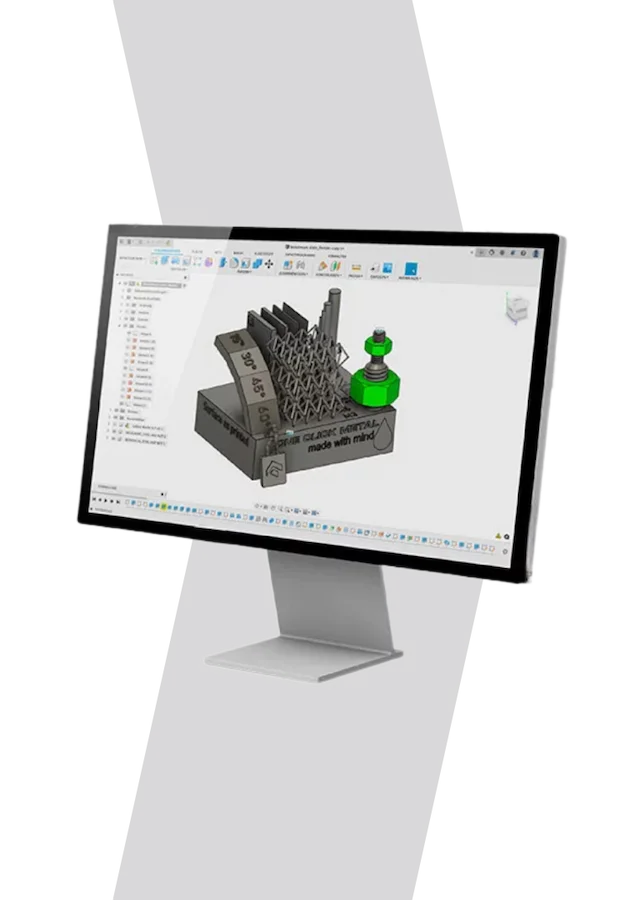

The advent of Industry 4.0 has brought about a transformative wave across various sectors, and the military/defense industry is no exception. This fourth industrial revolution is characterized by the integration of advanced technologies such as 3D printing, CAD software, and 3D scanning, which are revolutionizing the way defense operations are being conducted. Here, we explore the benefits and reasons behind the adoption of these cutting-edge technologies in military and defense.