Customer Success Story: RPG Industries

In this case study, we follow RPG Industries as they successfully implement Markforged 3D printing technologies. Continue reading for more details.

In this case study, we follow RPG Industries as they successfully implement Markforged 3D printing technologies. Continue reading for more details.

Like many other industries, the automotive market is reeling from the effects of disruption. Shifting consumer preferences have led to a realignment in production.

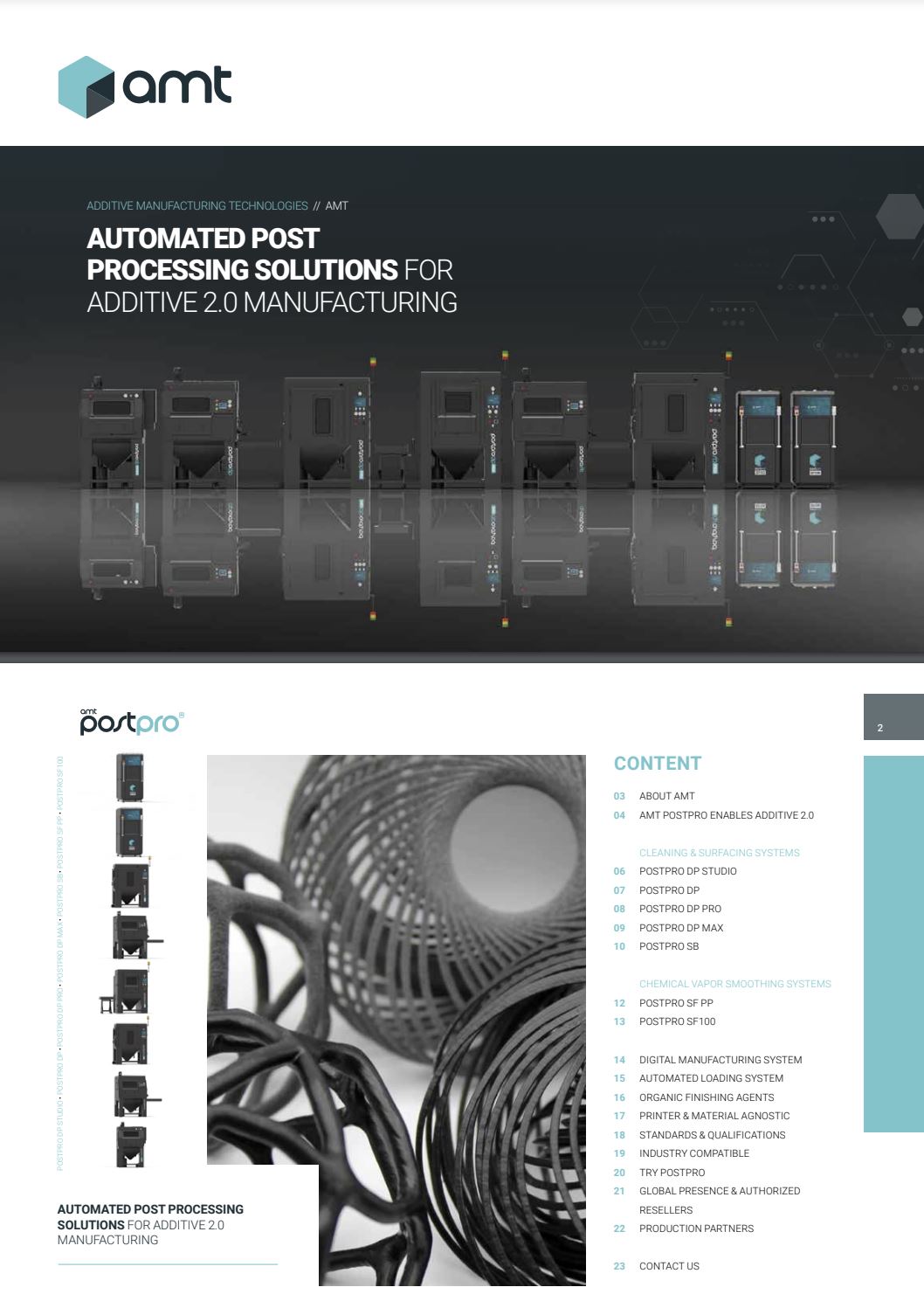

AMT’s automated post-processing solutions for additive manufacturing transforms 3D-printed parts into production-ready parts, consistently and quickly

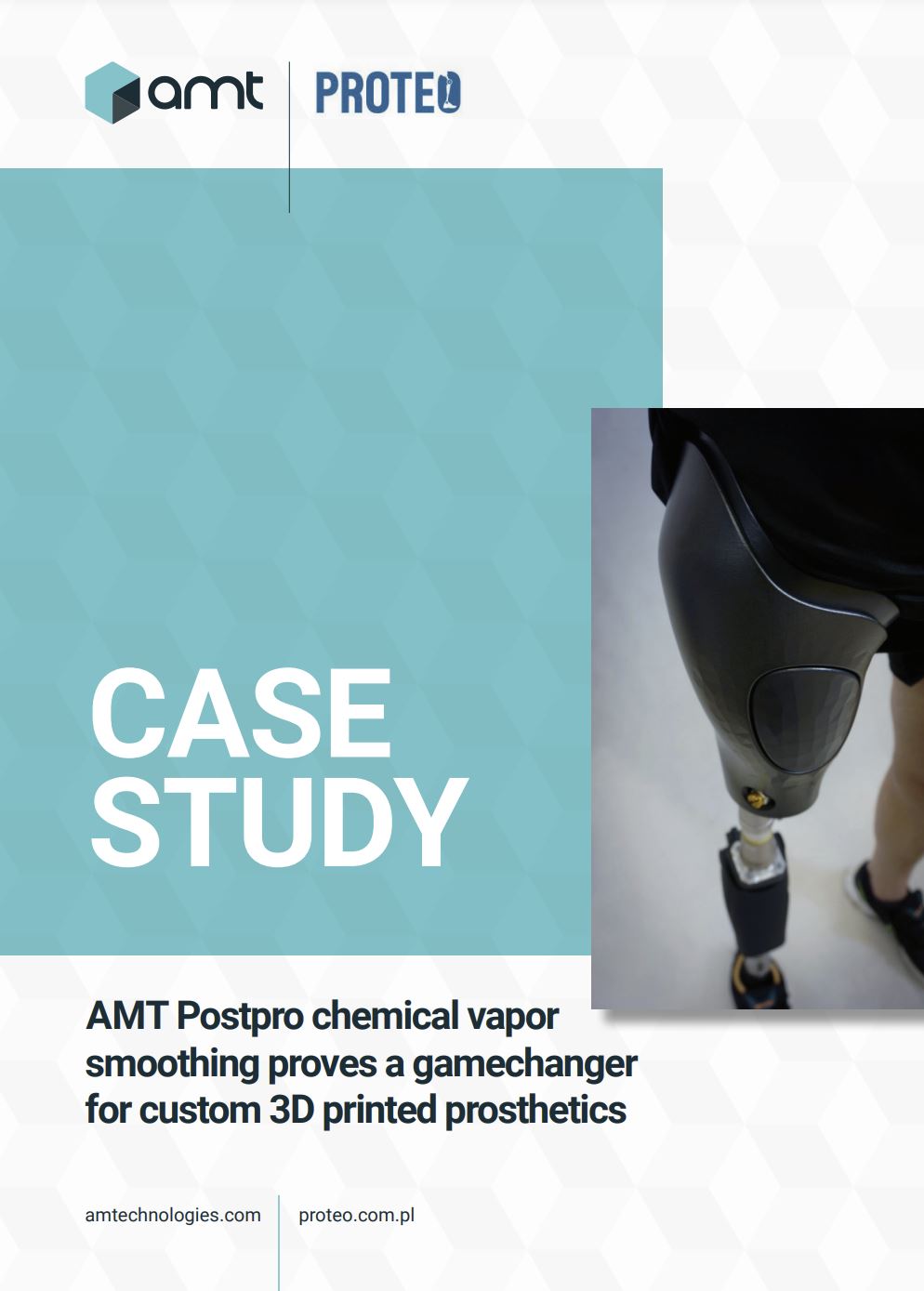

Proteo is one of the first companies to have successfully implemented 3D printing, CAD modeling, and 3D scanning for lower limb prosthetics. The DuoSocket prosthetic marks the next stage in the development of the company’s products, with which Proteo hopes to completely revolutionize the creation of prosthetics on a global scale.

In this case study, AutoDesk joins forces with GoPrint3D, and Leeds University to tackle student’s design challenge by utilizing Fusion 360 for design, Markforged X7 for 3D printing, and PostPro3D for sealing.

PRODUCTION OF A 3D PRINTED PART DOESN’T STOP AT THE PRINTER.

Post-processing is required to finish 3D printed parts for end-use. Traditional methods are slow, difficult to predict consistency, and can account for up to 60% of the part cost.

In this webinar, you will learn how 3D printing can enhance the learning experience of students and provide them with a deeper understanding of complex concepts and enhance their problem-solving skills.

Watch this on-demand webinar and learn how Ultimaker 3D printing solutions enable faculty and students to take the learning outside of the classroom and give them the ability to create

In this webinar, learn from our in-house expert, Alireza Pasha, on how HP Multi Jet Fusion technology streamlines production, cuts labor costs, and addresses supply chain challenges. Hear real-world examples and insights on its rapid design-to-solution process.

The aerospace industry leverages additive manufacturing (AM) for rapid response to supply chain shifts and labor availability. AM enables on-demand MRO, spare parts production, and innovation in Urban Air Mobility. This method simplifies manufacturing processes, allowing for unattended fabrication of end-use carbon fiber composites and high-performance thermoplastics, cutting lead times and costs. The e-book explores AM’s role in aerospace, compliance challenges, overlooked applications, advanced materials, and automated inspection technologies. Learn more in free e-book how AM is complimenting the aerospace industry.

CAD MicroSolutions is uniquely positioned to support our clients across Canada. Our team is dedicated to helping our customers ensure they are realizing the greatest value from their technology investment.

Complete the form below to subscribe to our newsletter.

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: Toll-free: 1-888-401-5885

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: 1-888-401-5885

Complete the form below and one of our team members will reach out to you as soon as possible to confirm your booking. If you need additional support, please contact us toll-free at: Toll-free: 1-888-401-5885