Customer Success Story: Cabin Management Solutions

Learn more about how aerospace companies are leveraging industry 4.0 technologies to innovate.

Learn more about how aerospace companies are leveraging industry 4.0 technologies to innovate.

In this case study we learn about how medical company Nivellmedical achieves their goal to enhance orthodontic aligner treatment with their innovative nivellipso dental aligner system using HP 3D printers. Continue reading to learn how HP accomplishes this.

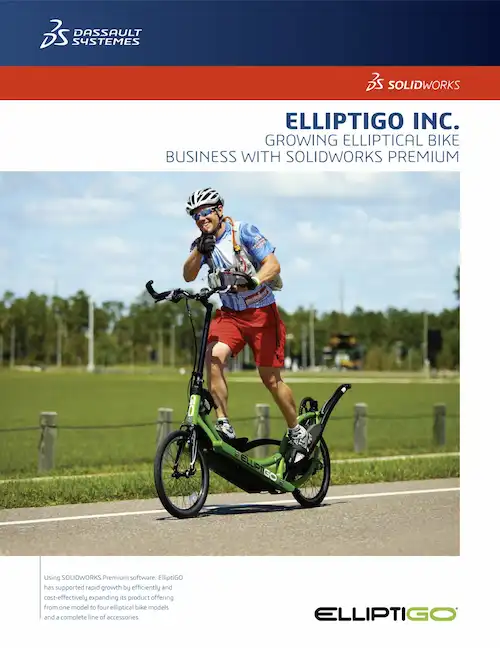

Learn how ElliptiGo is using SOLIDWORKS Premium software to support their company growth by efficiently and cost-effectively expanding its product offering from one model to four elliptical bike models and a complete line of accessories

In this case study learn how Siemens is using additive manufacturing to manufacture high-performing, complex parts faster than ever before.

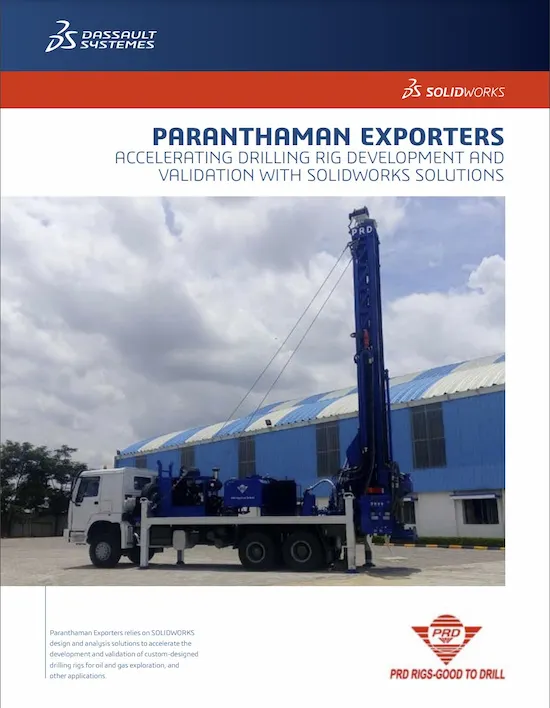

In this case study, read how Paranthaman Exporters relies on SOLIDWORKS design and analysis solutions to accelerate the development and validation of custom-designed drilling rigs for oil and gas exploration, and other applications.

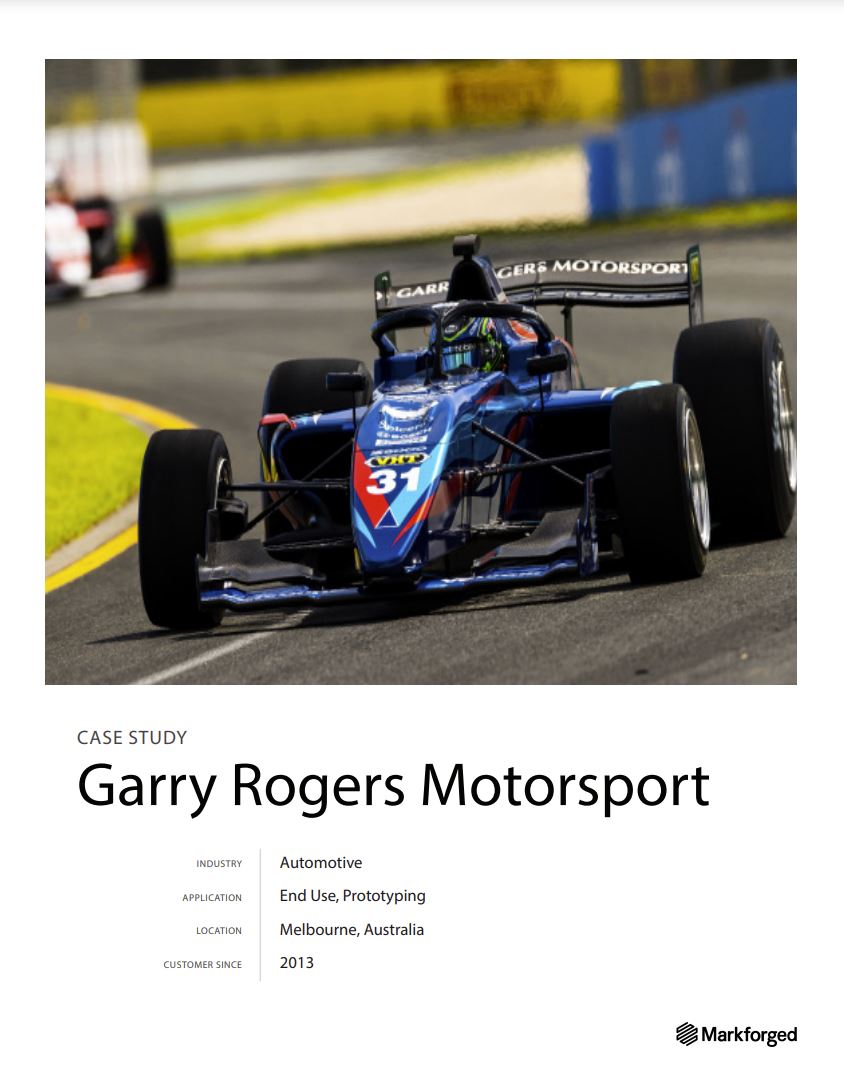

Garry Rogers Motorsport is Australia’s oldest motorsport team, securing wins in the nation’s Supercars Championship, Dunlop Super2 Series, and Bathurst 1000. The company has a team of nearly 40, with a focus on designing, building, and maintaining its own vehicles.

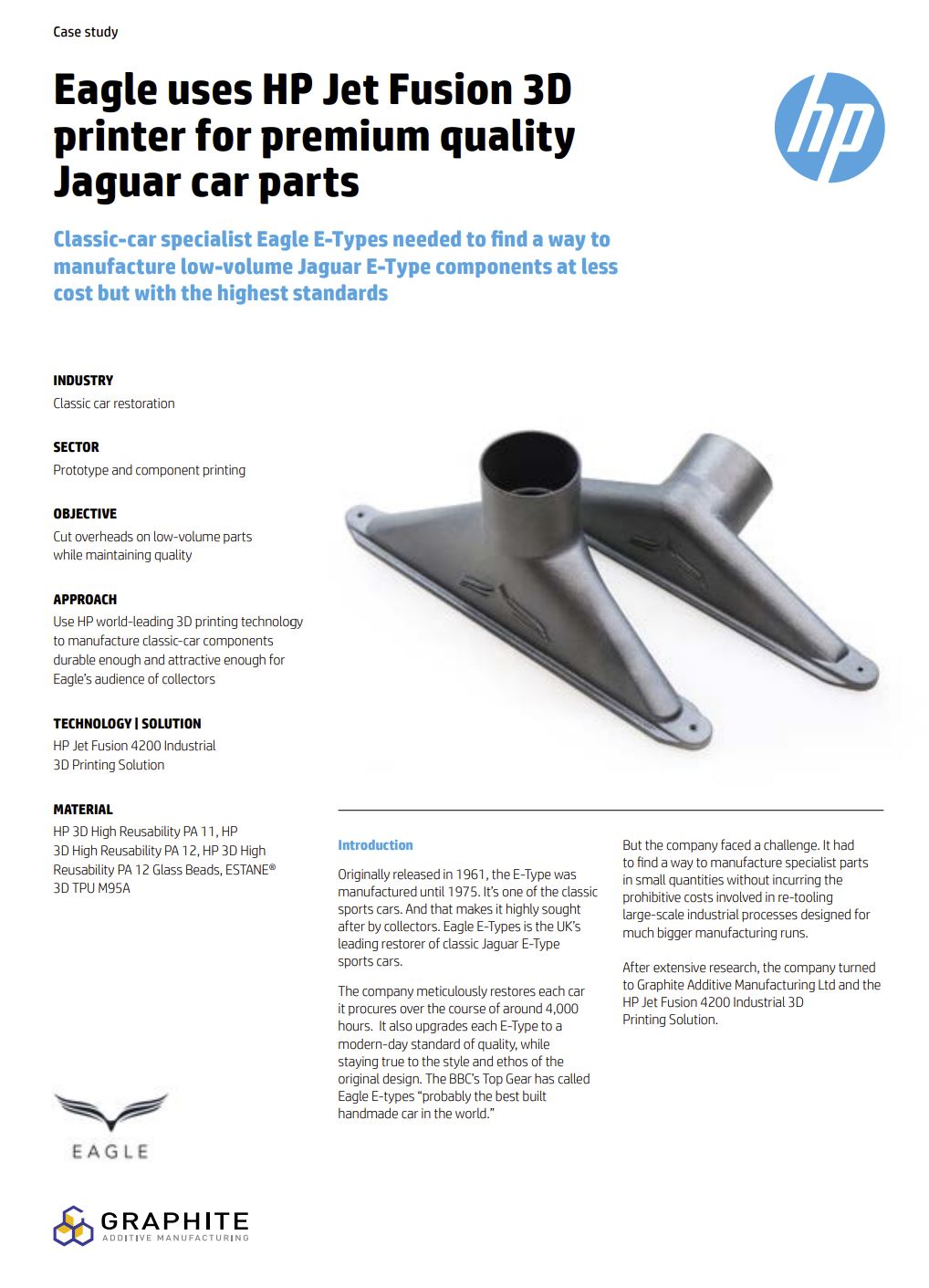

INDUSTRY Classic car restoration SECTOR Prototype and component printing OBJECTIVE Cut overheads on low-volume parts while maintaining quality APPROACH Use HP world-leading 3D printing technology to manufacture classic-car components durable

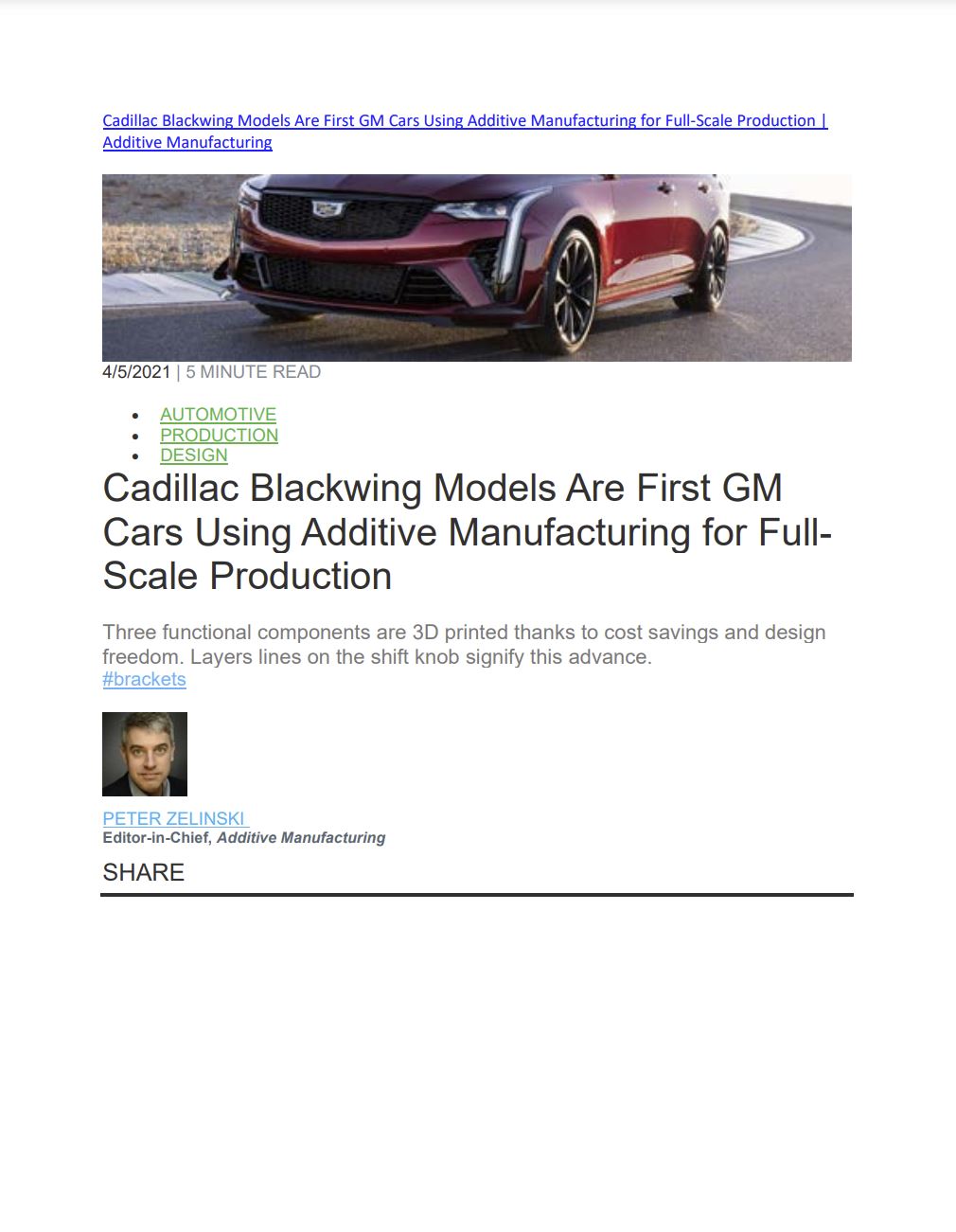

Additive manufacturing (AM) for full-scale production at the part quantities major automakers see is still a way off. However, General Motors sees that day coming, and is getting ready by seeking “pathfinder” additive manufactured parts that will allow the company to start facing and answering the questions that come from applying 3D printing for production.

In this case study, we follow RPG Industries as they successfully implement Markforged 3D printing technologies. Continue reading for more details.

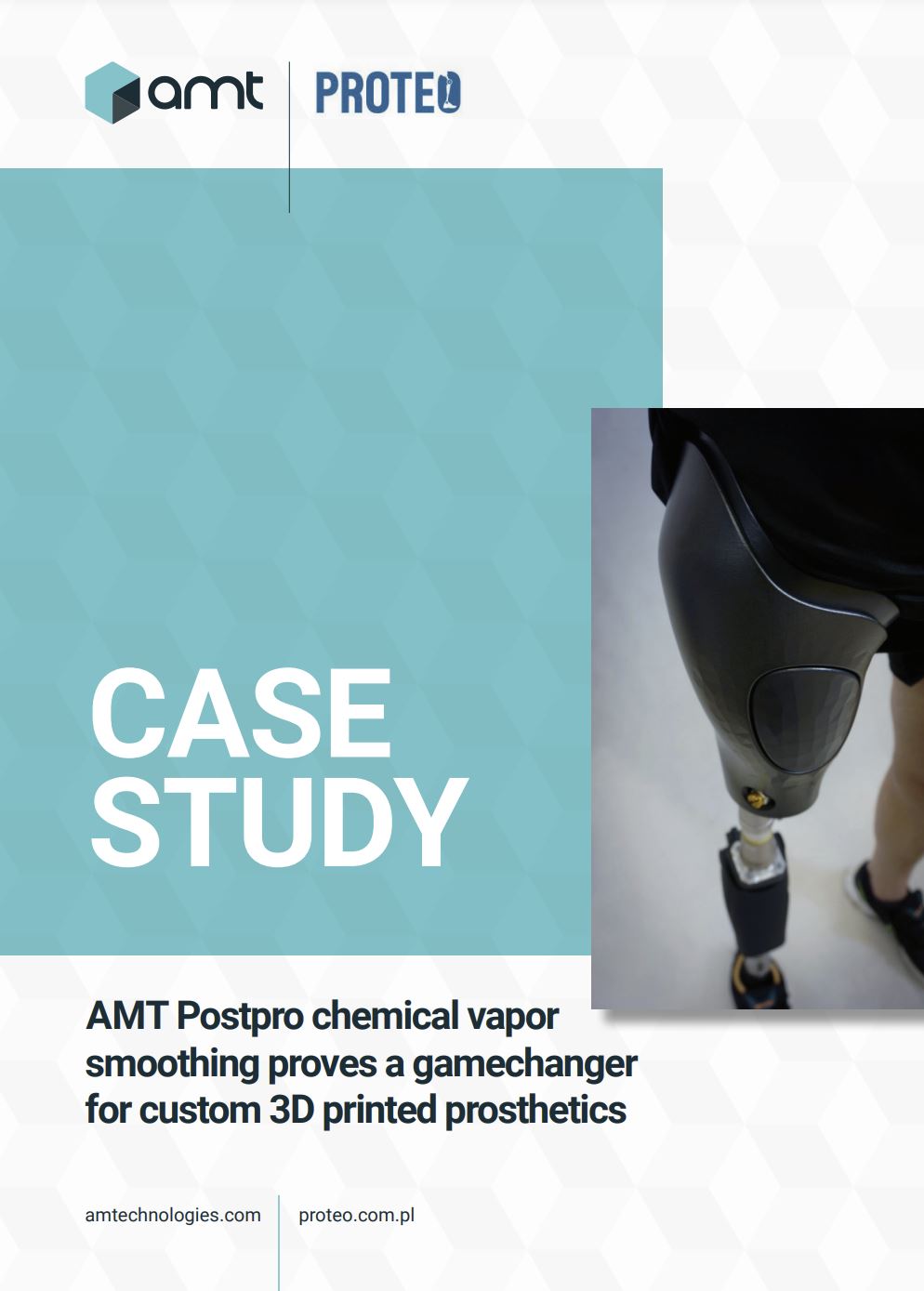

Proteo is one of the first companies to have successfully implemented 3D printing, CAD modeling, and 3D scanning for lower limb prosthetics. The DuoSocket prosthetic marks the next stage in the development of the company’s products, with which Proteo hopes to completely revolutionize the creation of prosthetics on a global scale.

CAD MicroSolutions is uniquely positioned to support our clients across Canada. Our team is dedicated to helping our customers ensure they are realizing the greatest value from their technology investment.

Complete the form below to subscribe to our newsletter.

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: Toll-free: 1-888-401-5885

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: 1-888-401-5885

Complete the form below and one of our team members will reach out to you as soon as possible to confirm your booking. If you need additional support, please contact us toll-free at: Toll-free: 1-888-401-5885