Why Your Company Should Be Implementing Data Management Software: The Benefits of SOLIDWORKS PDM

Written by | Prableen Sachdeva

February 19, 2025

| 9:01 am

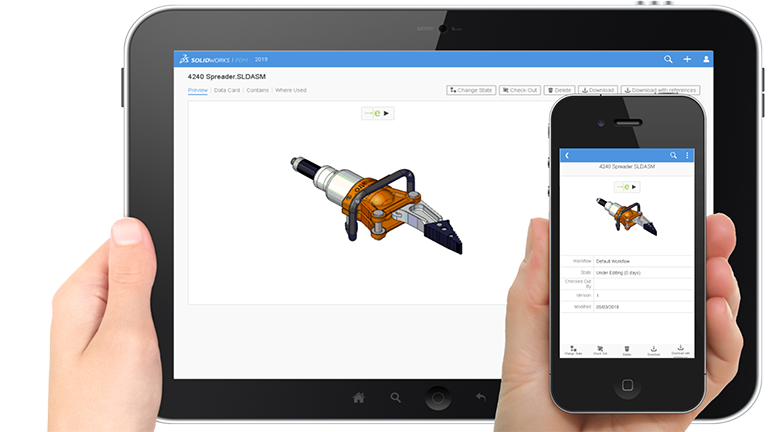

In today’s fast-paced and competitive business environment, managing product data efficiently is more important than ever. Companies in industries like manufacturing, engineering, and design are continuously creating and refining product models, CAD files, drawings, and documentation. However, without proper data management, these valuable assets can quickly become disorganized, leading to costly mistakes, missed deadlines, and lost opportunities. This is where SOLIDWORKS PDM (Product Data Management) comes in – a powerful tool designed to streamline data management and help companies maintain control of their valuable design data.

Here are the key benefits of implementing SOLIDWORKS PDM:

Here are the key benefits of implementing SOLIDWORKS PDM: How CAD Micro Can Help

How CAD Micro Can Help