Healthcare Innovations

One of the most significant areas of growth has been in healthcare. Additive manufacturing (AM) has enabled the production of personalized medical devices, such as implants and surgical tools, directly within hospitals and surgical centers. This not only improves patient outcomes but also reduces costs and supply chain dependencies. The dental industry has also benefited, with AM facilitating the direct production of custom prosthodontics and orthodontics.

Aerospace and Defence

The aerospace and defence sectors have continued to leverage AM for both direct and indirect manufacturing processes. The ability to produce complex, high-performance parts with precision has been crucial in addressing supply chain challenges and enhancing the capabilities of aerospace equipment. This year, we saw significant advancements in the use of metal technologies, such as laser powder bed fusion, which have enabled the production of parts that can withstand extreme conditions.

Consumer Goods

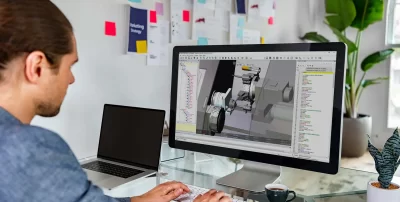

In the realm of consumer goods, AM has moved beyond prototyping to full-scale production. This shift has been particularly evident in the electronics industry, where the technology has enabled faster product development and the creation of innovative designs that were previously impossible with traditional manufacturing methods. The ability to combine form and function early in the design process has led to the development of products that offer enhanced performance and aesthetic appeal.

Automotive Industry

The automotive industry has also embraced AM, with notable applications in safety and performance enhancements. For instance, IndyCar implemented 3D printing to develop a top frame that increases drive safety by protecting against debris and potential rollovers. This application highlights the unique advantages of AM in producing complex shapes and structures under tight time constraints.

Semiconductor Manufacturing

AM has played a pivotal role in addressing the ongoing semiconductor shortage. The technology’s ability to produce highly complex parts with exacting accuracy has accelerated the development of semiconductor equipment, improving performance and reducing time-to-market. Innovations in thermal management and fluid flow optimization have further enhanced the efficiency and reliability of semiconductor manufacturing processes.

Sustainability and Localized Production

Sustainability has been a key focus in 2024, with AM contributing to more environmentally friendly manufacturing practices. By enabling localized production, AM reduces the need for extensive logistics and transportation, thereby minimizing carbon footprints. This trend towards on-shore production has provided businesses with greater flexibility and resilience, particularly in times of global supply chain disruptions.

Events and Collaborations

This year also saw significant industry events, such as RAPID + TCT, which showcased groundbreaking advancements and fostered collaboration among industry leaders. Additionally, companies like Nikon and Hitachi Rail have made strides in integrating AM into their operations, further demonstrating the technology’s versatility and impact.

As we look ahead, the future of additive technology appears brighter than ever. The innovations of 2024 have set the stage for continued growth and transformation across multiple sectors, promising even greater advancements in the years to come.