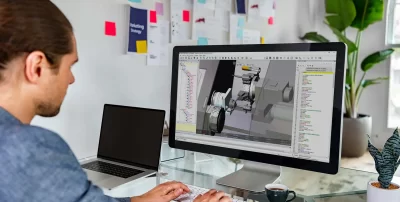

Uniting Forces: How and Why SOLIDWORKS and Cadence Should Be Used Together

Written by | Prableen Sachdeva

January 29, 2025

| 9:05 am

In the realm of engineering and design, the integration of different software tools can significantly enhance productivity and innovation. SOLIDWORKS and Cadence, two leading platforms in their respective fields, offer a powerful combination when used together. This blog explores how and why these tools should be integrated, highlighting the benefits and potential applications of their combined use.