Innovations in Metal 3D Printing: One click Metal and the LPBF Process

Written by | Prableen Sachdeva

December 31, 2024

| 9:00 am

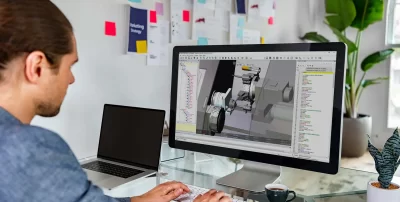

One Click Metal is making significant strides in the field of additive manufacturing with its innovative approach to metal 3D printing. Central to their technology is the Laser Powder Bed Fusion (LPBF) process, a cutting-edge method that offers unparalleled precision and efficiency. Let’s explore how One Click Metal and LPBF are transforming the landscape of metal 3D printing.