Transforming Manufacturing with DELMIA

Written by | Prableen Sachdeva

August 7, 2024

| 9:00 am

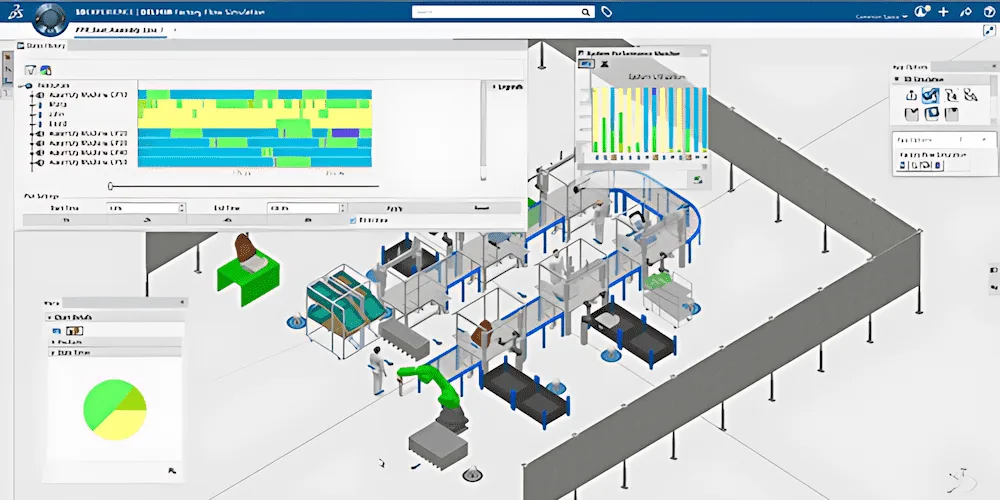

In today’s world of manufacturing, the need for precision, efficiency, and innovation is paramount. DELMIA offers comprehensive solutions that empower professionals to excel in their roles and drive manufacturing excellence. This blog explores three crucial roles within DELMIA: Factory Simulation Engineer, Robot Programmer, and NC Shop Floor Programmer. Additionally, we invite you to join our upcoming webinar series to delve deeper into these roles and learn how they can revolutionize your manufacturing processes.