3DEXPERIENCE Cloud PLM Premium

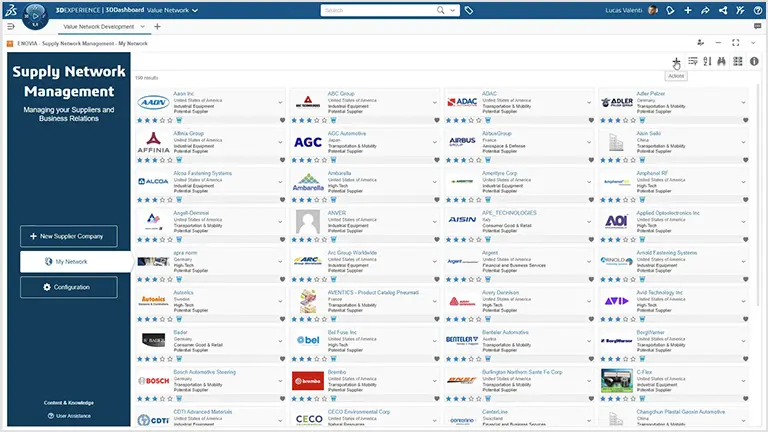

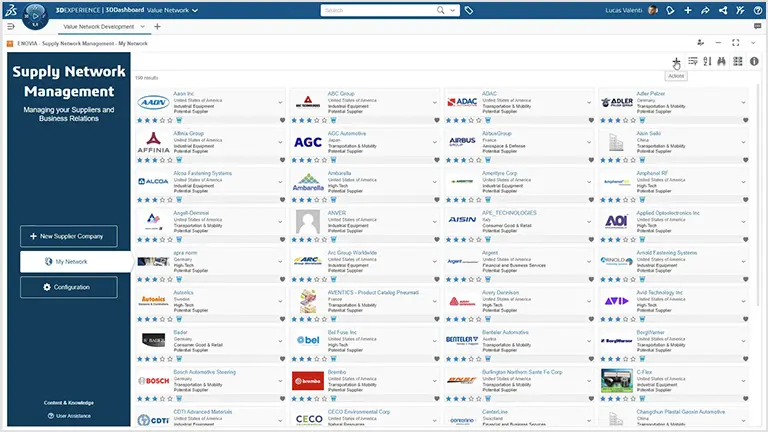

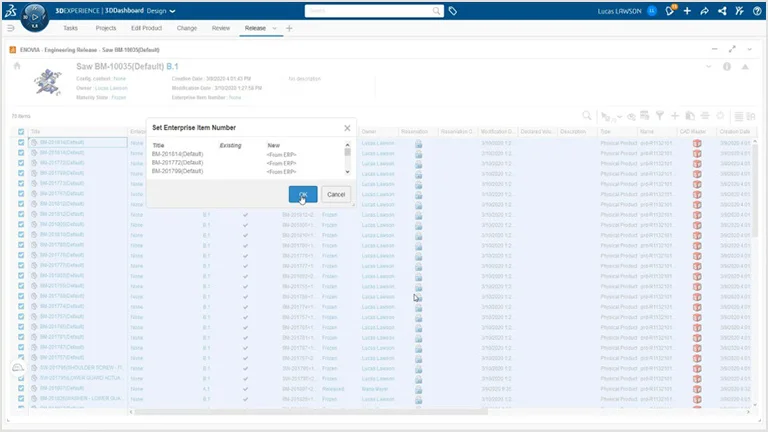

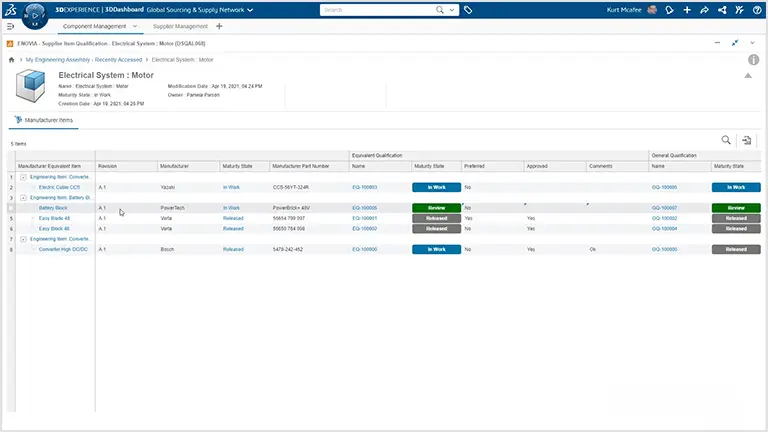

3DEXPERIENCE Cloud PLM Premium training course helps users learn to utilize IP classification for library components, manage supplier network and items, and integrate the 3DEXPERIENCE platform with ERP.

3DEXPERIENCE Cloud PLM Premium training course helps users learn to utilize IP classification for library components, manage supplier network and items, and integrate the 3DEXPERIENCE platform with ERP.

The 3DEXPERIENCE Cloud PLM Professional training course helps users learn to manage and edit product structures (including in 3D) and execute a traceable, formal change management processes that are connected to their CAD data.

The 3DEXPERIENCE Cloud PLM Standard training course helps users learn to plan and optimize project schedules and manage their product BOMs on the cloud with advanced viewing, filtering, and editing tools.

Complete the form below and one of our team members will reach out to you as soon as possible to confirm your booking. If you need additional support, please contact us toll-free at: Toll-free: 1-888-401-5885