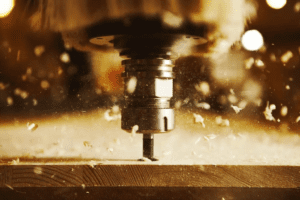

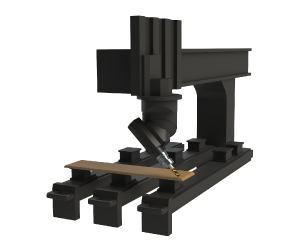

SWOOD CAM Training (Without Nesting) Course Outline

The course enables students to learn the SWOOD CAM interface and best practices. More specifically, users will learn to create machine tools and aggregates, program machinable features both automatically and interactively, and learn 4th and 5th axis programming. In addition, training items include toolpath simulation, post processing, generating shop reports and SWOOD CAM Nesting capabilities (additional module).