Marking Systems

Laser marking is a fast, flexible solution for many additive manufacturing processes. CAD MicroSolutions is an authorized Trumpf TruMark Marking

3d printers

The right 3D printers for your industrial Manufacturing processes

Compact and robust 3D printing

The TruPrint 1000 is the most productive machine in compact form and offers you all the benefits of additive manufacturing. The build volume (cylinder) is 100 mm in diameter and a height of 100 mm. This can be reduced for precious metals. The TruPrint 1000 can be used to create components in almost any geometric shape. Even relatively complex shapes can be quickly and easily converted from the CAD design to a 3D metallic component – with top quality.

Compact and robust 3D printing

Highest build rates and machine runtimes

Excellent part and surface quality

Ergonomic, contactless powder handling

Process flexibility and expanded monitoring

Best solution for dental applications

Economical 3D printing with premium quality

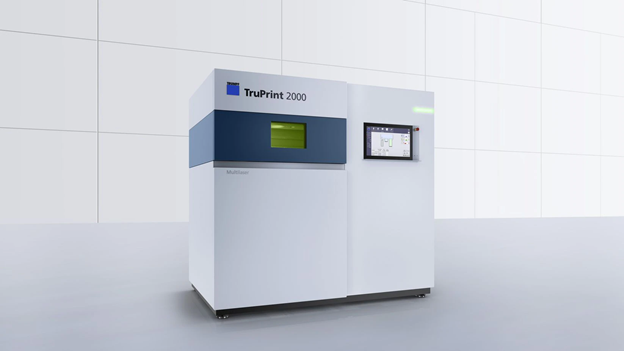

Economical 3D printing with premium quality

Highly productive premium component quality

Low costs per part

The highest quality standards

Simple operation

Can be individually adapted

With its small 55-µm laser beam diameter, the TruPrint 2000 provides a high-quality printing result which impresses with its surface quality and level of detail. It offers a build volume (cylinder) of 200 mm in diameter and a height of 200 mm. The fullfield multilaser with two 300-watt fiber lasers from TRUMPF – which scan the entire build area – delivers top productivity. Melt Pool Monitoring and comprehensive process monitoring ensure the highest quality standards. The production process with the TruPrint 2000 is a closed powder circuit under shielding gas. This allows for easy and practical handling, with the highest operator safety.

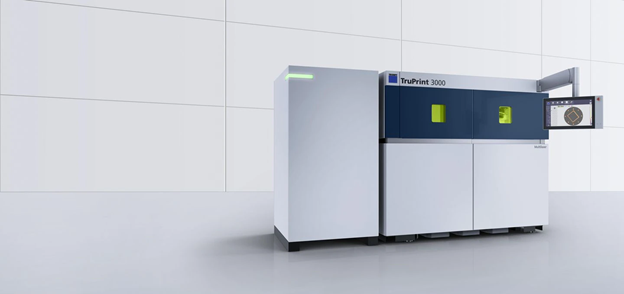

Flexible solution for industrial 3D printing

Productivity is almost doubled, independent of the component geometry, and the part costs are significantly decreased. Automatic monitoring and calibration of the multilasers during the build job facilitates optimum quality for printed multilaser components. The latest developments in shielding gas control additionally increase the component quality and reproducibility of the parts. This is documented parallel to the build job thanks to Melt Pool Monitoring.

High level of process robustness

Full-field multi-laser 2 x 500 watts

Flexible production setup

Extensive monitoring solutions

Inert, closed powder circuit

Highly productive 3D printing for industrial serial production

Highly productive 3D printing for industrial serial production

The highly productive, partially automated TruPrint 5000 3D printing system provides the ideal basis for industrial series production. With optional features, including 500°C-preheating and the fullfield multilaser with three 500-watt TRUMPF fiber lasers, you are perfectly equipped to handle even the most demanding industrial applications. The machine quickly and reliably produces high-quality components made of different metallic materials – and in doing so meets the high quality requirements in tool and mold making, including by means of 3D printing on preform blanks, in aerospace and medical technology. As an option, the entire process chain can be carried out in a shielding gas atmosphere: sieving, printing, cooling, depowdering. Combined with external part and powder management and the monitoring solutions from TRUMPF, it is predestined for industrial additive series production.

Maximum productivity

High component quality

Automatic process start

Hybrid manufacturing thanks to Preform

External part and powder management

Industrial monitoring

The TruPrint 5000 Green Edition combines expertise in additive manufacturing with cutting-edge industrial beam sources to enable 3D printing of highly reflective materials such as copper. With a larger build volume than the previous TruPrint 1000 Green Edition, this printer enables new applications for manufacturing induction coils, components for complex cooling applications, and high performance heat exchangers for power electronics and optoelectronics, as well as electric motor development and other high-end applications that benefit from the conductive properties of copper.

Highly conductive pure copper ETP enables an electrical conductivity of 100% IACS

Ability to print highly reflective materials, including copper and copper alloys

Highest quality and productivity of printed pure copper and copper alloys

Designed for high thermal load – no risk of laser degradation

OPTIMAL POWDER HANDLING FOR MAXIMUM PRODUCTIVITY

Optimal handling of the powder and components is crucial for additive series production on an industrial scale. The industrial part and powder management from TRUMPF enables you to increase productivity and profitability in your production operations as setup and powder removal on one or more TruPrint machines can be performed parallel to production.

High productivity

Clean production

Short throughput times

Great flexibility

Powder handling under shielding gas

Our CEC provides an opportunity for customers to see, touch and interact with the technology behind Industry 4.0 – so you can try before you buy.

RESOURCES

Laser marking is a fast, flexible solution for many additive manufacturing processes. CAD MicroSolutions is an authorized Trumpf TruMark Marking

CAD MicroSolutions Inc. is uniquely positioned to support our clients across Canada. Visit one of our 5 locations, or contact

Explore our comprehensive catalog of industrial 3D printers, we offer cutting-edge technology for precise manufacturing. Stay ahead of the competition.

CAD MicroSolutions is uniquely positioned to support our clients across Canada. Our team is dedicated to helping our customers ensure they are realizing the greatest value from their technology investment.

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: 1-888-401-5885

Complete the form below to subscribe to our newsletter.

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: Toll-free: 1-888-401-5885

Complete the form below and one of our team members will reach out to you as soon as possible to confirm your booking. If you need additional support, please contact us toll-free at: Toll-free: 1-888-401-5885